SDI is the front runner

in dip coats

We design, manufacture, and sell equipment as a manufacturer specializing in dip coaters.

Many of the coating liquids used for surface treatment are high value-added and expensive products,

and many users are wondering how to reduce the amount of coating liquid used to achieve a thinner film.

Our dip coaters are the best choice for such users.

What is dip coater?

Dip coater is a device that forms thin films on both sides simultaneously by dipping the workpiece (base material) to be dip coated into the dip coating solution and pulling it upward.

The device is used for manufacturing and research in many fields, such as surface hardener coating of eyeglass lenses, polycarbonate, acrylic materials, etc., resist coating on printed circuit boards and glass, and particle alignment on glass.

SDI offers a wide range of products from tabletop dip coaters for laboratory use to dip coaters for production use.

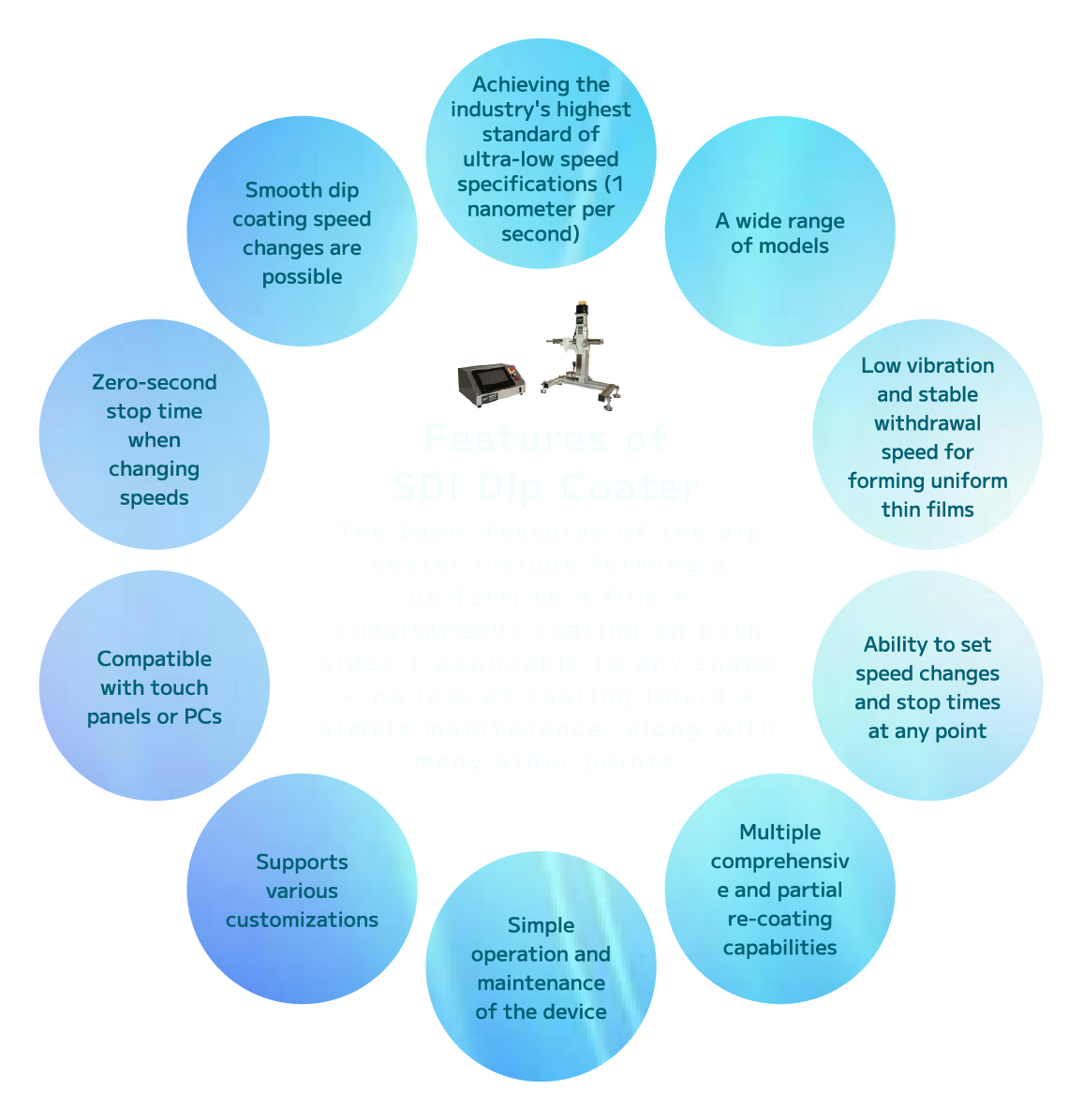

What are the features of SDI's dip coating equipment (dip coater)?

We have a diverse lineup of equipment ranging from ultra-low speed specifications to mass production equipment. Basically, we provide customized specifications and are committed to providing original equipment. The product lineup covers a wide range of processing speeds from 1 nm/sec to 200 mm/sec for the dip coater speed range, enabling uniform thin film formation due to uneven speed and low vibration. In addition, the touch panel system allows easy operation. Of course, it is also compatible with PCs.

What kind of delivery records do we have?

Please see the list of SDI Dip Coater customers from the "List of Our Customers". We have delivered our products to a wide variety of fields, including public institutions, schools, manufacturers, and overseas. We can also manufacture jigs for dip coaters. We believe that there are as many jigs as there are customers. We provide the best-matched jigs based on our experience in manufacturing a large number of jigs. The standard delivery time for a regular dip coater is 45 days after receiving an order. For custom-made dip coaters, please contact us for a separate consultation. Please feel free to contact us.

Q&A

- What is a dip coater (dip coating method)?

- What film thickness is possible with the dip coating method?

- How can the film thickness be controlled by the dip coating method? What is the accuracy of the film thickness?

- I would like to do particle array. Is it possible with your dip coater?

- What are the features of SDI's dip coating equipment (dip coaters)?

- Is it possible to change the speed during dip coating?

- What types of equipment are available for dip coating and drying?

- What types of substrates (workpieces) can be dip-coated?

- What is the repeatability of the dip coater system?

- How is it operated?

- Is it possible to fabricate a tank for dip coating?

- What should be considered when using a dip coater?

- What are the differences from other coating methods?

- How much does a dip coating system cost?

- What is the turnaround time for dip coaters?

- What is the delivery record of your dip coaters?

- Can you manufacture a jig for a dip coater?

- What kind of mechanism is a dip coating solution circulator?

- What kind of maintenance is involved in dip coaters?

Let's take a look at SDI's features

* Features of our dip coaters (dip coating equipment) vary depending on the model.

Detailed features shown in the video

All for your satisfaction

Contract Coating

We provide contract coating services using a dip coater in a clean room.

We provide consistent service from the prototype stage to incoming inspection, pre-shipment inspection, packaging, and shipping.

Furthermore, since there is no need to purchase the device, it is possible to reduce the initial costs. We can also recommend coating liquids. Please feel free to contact us.

As a designer and manufacturer, we are able to customize our products with the utmost care and attention to detail.

If you have any requests or questions, please feel free to contact us.

-

Inquiries by Phone

Business hours: 9:00 to 17:00

* Excluding Saturdays, Sundays,

public holidays, and substitute holidays -

Inquiries via facsimile

075-323-0237

Business hours: 24-Hour Reception

Japanease

Japanease English

English

Contact us by email

Contact us by email